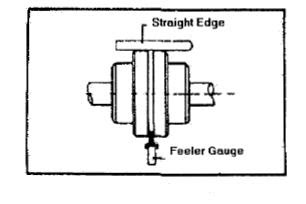

The pump set to be aligned radial and axial within 0.1mm by installing dial indicators as shown in fig no.1 and without pipe connection. The gap between the two coupling halves must be the same at all points (minimum 3 points) on the circumference, this can be measured using caliper or a feeler gauge.

The alignment should be carried with & without pipe connections and should limits. For liquids handling more than 150 C, cold alignment & hot alignment both should be carried out on pump set.